Story of the Month: Independencia II Mooring

Reinforcing Independence:

OOS-Enabled Independencia II Mooring System Upgrade

The maritime industry demands constant innovation, pushing the boundaries of logistics to achieve ambitious goals. We thrive on these challenges at Gulf Copper Energy Services (GCES). Our recent work on the OOS-enabled Independencia II, a heavy-lift vessel operating in demanding offshore environments, exemplifies our commitment to delivering complex projects with precision and efficiency. This wasn’t just maintenance but a transformation, bolstering the vessel’s capabilities and extending its operational lifespan.

The project centered around a significant upgrade to the vessel’s mooring system foundation. This involved enhancing the vessel’s structural integrity to accommodate two fairleads on each column and two winches on each deck’s four corners—a crucial upgrade for increased stability and operational flexibility in challenging offshore conditions. The scale of this undertaking was substantial, requiring the installation of 160 tons of prefabricated steel, meticulously distributed with 40 tons allocated to each column.

Our scope extended beyond mere installation. It encompassed a comprehensive approach, from the initial fabrication and assembly of components at our Galveston yard to the final installation and alignment of critical machinery onboard the vessel. This included precise winch gearbox and motor alignment, ensuring optimal performance and longevity, and fitting operator cabins for enhanced crew comfort and operational control.

The project commenced in early September 2024 and is expected to conclude in mid-March 2025. The fabrication phase alone, conducted at our state-of-the-art Galveston facility, demanded approximately 20,000 man-hours of skilled labor. Our team meticulously cut, prepped, and welded steel components into precise installation pieces, adhering to the highest quality and safety standards.

The logistical complexities of this project were considerable. Transporting the fabricated steel, specialized tools, and essential equipment required a carefully orchestrated multi-modal approach. 162 pallets were dispatched via 31 truck shipments from our GCES facility to the shipping company in Fort Lauderdale, Florida, with departures staggered between September 21, 2024, and January 13, 2025. From there, 13 separate sea freight shipments conveyed the cargo to Curacao, where the Independencia II was located.

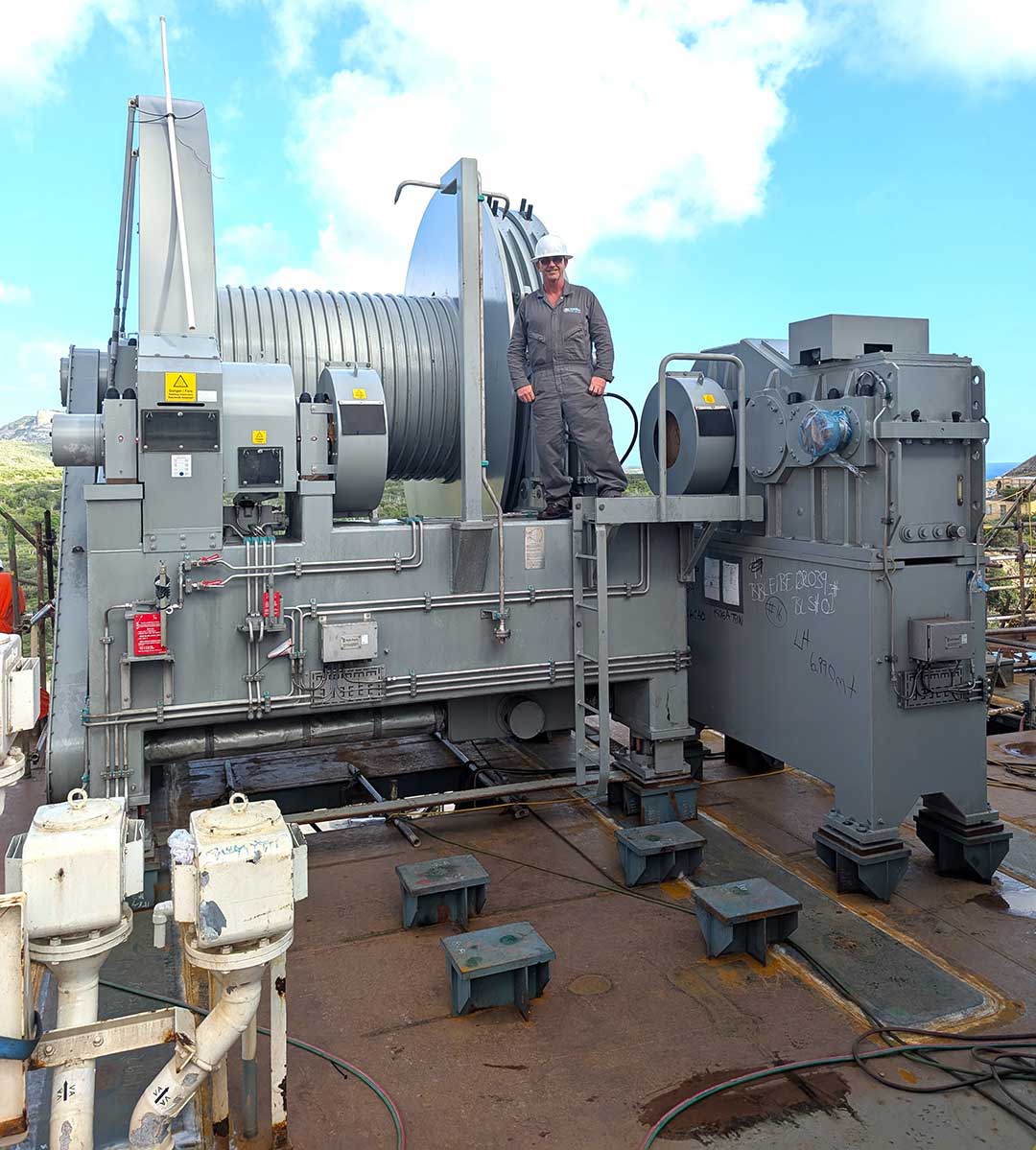

Independencia II SF Winch

On board the vessel, a dedicated team of 65 skilled professionals worked tirelessly to execute the installation. Led by Shaun Flower (Project Manager) and Emilio Guzman (Project Supervisor), the team included seven additional supervisors overseeing a highly trained workforce of welders and fitters sourced from our Mexico office. This collaborative effort resulted in approximately 70,000 onboard man-hours, encompassing the core installation and additional tasks crucial to the vessel’s operational readiness.

The success of this project is not just measured in tons of steel or man-hours but also in the positive feedback received from our client. Christopher Stephen Hawkins, Project Planner/Document Controller for OOS, commended our team’s professionalism and near-perfect safety record. He specifically highlighted the strong leadership of Shaun and Emilio, recommending them for advancement, and praised the dedication and skill of the entire welding and fitting crews. Further feedback from OOS Project Manager Eddie Sarkis acknowledged the excellent quality of work, strong supervision, and the team’s adaptability in performing tasks beyond their assigned trades. He noted their willingness to assist with winch alignment and responsiveness to changing project requirements.

The Independencia II project underscores GCES’s capabilities in delivering complex, large-scale marine solutions. We are proud of our team’s dedication, expertise, and commitment to safety and quality, and we look forward to continuing to provide innovative solutions for the maritime energy sector.