Story of the Month: The TX-10000 Project

Innovating Maritime Solutions: The TX-10000 Project

We at Gulf Copper and Manufacturing and Gulf Copper Energy Services (GCES) are excited to share some thrilling news regarding our ongoing support for the TX-10000, the largest heavy-lift vessel in the United States. Our team has been diligently working to ensure that this remarkable vessel operates at peak performance, and we are proud to announce that we will be undertaking essential maintenance during its upcoming stay at our facility on the 35,000-t dry dock in Galveston.

This maintenance will include critical tasks such as repainting and thruster servicing, vital for the TX-10000’s operational efficiency. Our dedicated GCES team has provided rigging, lifting, inspections, and HSE support for several years, ensuring that the vessel remains in top condition while out in the field. Our shipyard team will now dry dock the vessel.

Story of the Month: Independencia II Mooring

Reinforcing Independence:

OOS-Enabled Independencia II Mooring System Upgrade

The maritime industry demands constant innovation, pushing the boundaries of logistics to achieve ambitious goals. We thrive on these challenges at Gulf Copper Energy Services (GCES). Our recent work on the OOS-enabled Independencia II, a semi-submersible offshore drilling rig operating in demanding offshore environments, exemplifies our commitment to delivering complex projects with precision and efficiency. This wasn’t just maintenance but a transformation, bolstering the vessel’s capabilities and extending its operational lifespan.

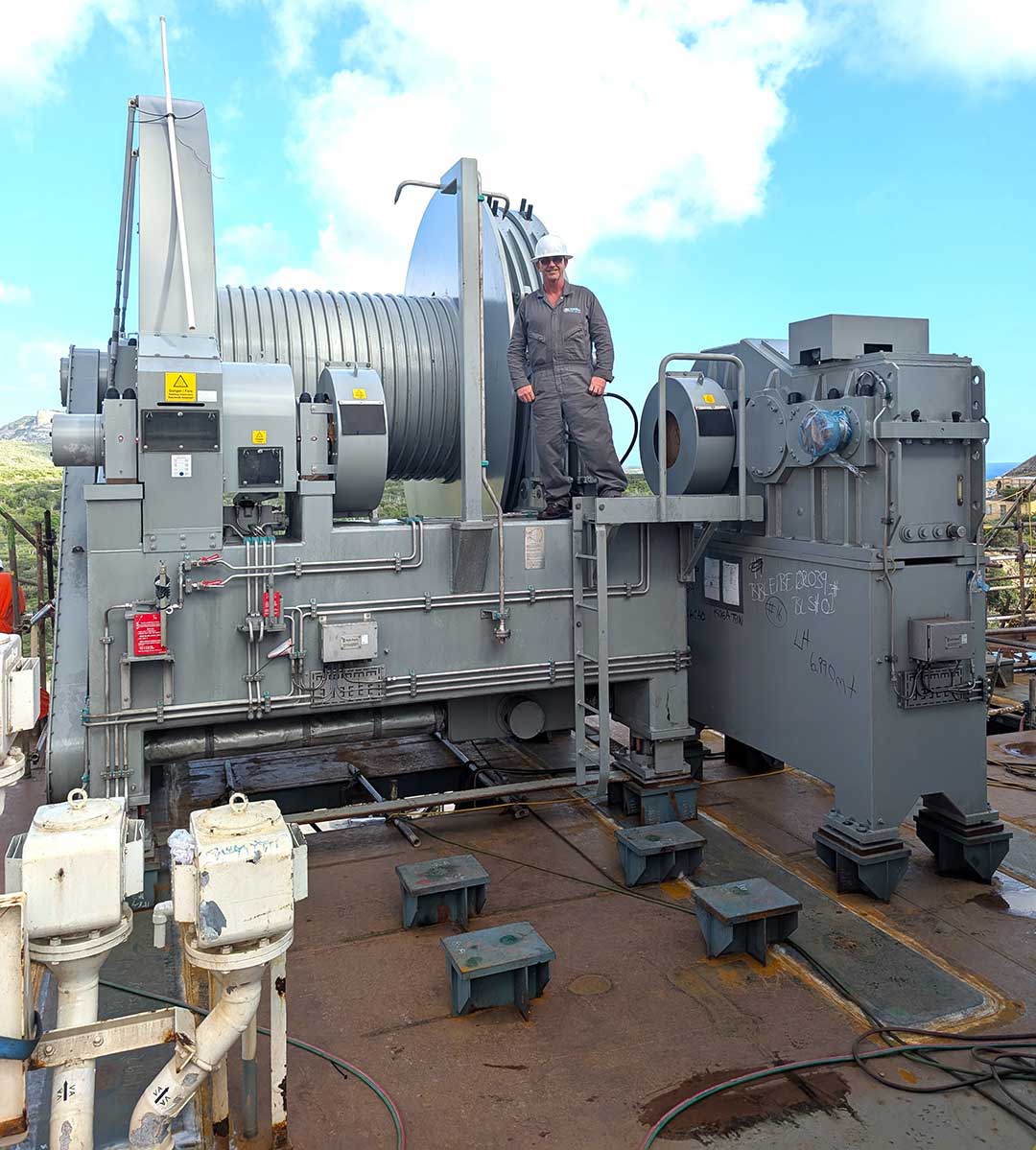

The project centered around a significant upgrade to the vessel’s mooring system foundation. This involved enhancing the vessel’s structural integrity to accommodate two fairleads on each column and two winches on each deck’s four corners—a crucial upgrade for increased stability and operational flexibility in challenging offshore conditions. The scale of this undertaking was substantial, requiring the installation of 160 tons of prefabricated steel, meticulously distributed with 40 tons allocated to each column.

Our scope extended beyond mere installation. It encompassed a comprehensive approach, from the initial fabrication and assembly of components at our Galveston yard to the final installation and alignment of critical machinery onboard the vessel. This included precise winch gearbox and motor alignment, ensuring optimal performance and longevity, and fitting operator cabins for enhanced crew comfort and operational control.

The project commenced in early September 2024 and is expected to conclude in mid-March 2025. The fabrication phase alone, conducted at our state-of-the-art Galveston facility, demanded approximately 20,000 man-hours of skilled labor. Our team meticulously cut, prepped, and welded steel components into precise installation pieces, adhering to the highest quality and safety standards.

The logistical complexities of this project were considerable. Transporting the fabricated steel, specialized tools, and essential equipment required a carefully orchestrated multi-modal approach. 162 pallets were dispatched via 31 truck shipments from our GCES facility to the shipping company in Fort Lauderdale, Florida, with departures staggered between September 21, 2024, and January 13, 2025. From there, 13 separate sea freight shipments conveyed the cargo to Curacao, where the Independencia II was located.

Independencia II SF Winch

On board the vessel, a dedicated team of 65 skilled professionals worked tirelessly to execute the installation. Led by Shaun Flower (Project Manager) and Emilio Guzman (Project Supervisor), the team included seven additional supervisors overseeing a highly trained workforce of welders and fitters sourced from our Mexico office. This collaborative effort resulted in approximately 70,000 onboard man-hours, encompassing the core installation and additional tasks crucial to the vessel’s operational readiness.

The success of this project is not just measured in tons of steel or man-hours but also in the positive feedback received from our client. Christopher Stephen Hawkins, Project Planner/Document Controller for OOS, commended our team’s professionalism and near-perfect safety record. He specifically highlighted the strong leadership of Shaun and Emilio, recommending them for advancement, and praised the dedication and skill of the entire welding and fitting crews. Further feedback from OOS Project Manager Eddie Sarkis acknowledged the excellent quality of work, strong supervision, and the team’s adaptability in performing tasks beyond their assigned trades. He noted their willingness to assist with winch alignment and responsiveness to changing project requirements.

The Independencia II project underscores GCES’s capabilities in delivering complex, large-scale marine solutions. We are proud of our team’s dedication, expertise, and commitment to safety and quality, and we look forward to continuing to provide innovative solutions for the maritime energy sector.

Scenic Eclipse Back in Action

Scenic Eclipse Back in Action Thanks to Gulf Copper’s Swift Drydock Expertise

The luxury expedition ship Scenic Eclipse has returned to service following critical repairs conducted at Gulf Copper’s Galveston shipyard. The vessel, known for its adventurous itineraries, experienced propulsion issues in September, necessitating an urgent drydock to replace a faulty Azipod.

Gulf Copper’s team swiftly responded to the challenge, accommodating the 228-guest ship and facilitating the complex repair process. Remarkably, the replacement Azipod was delivered to the shipyard via a chartered Antonov 124 aircraft, one of the world’s largest cargo planes, highlighting the scale and urgency of the operation.

Story of the Month: GCES Rope Teams Rise to the Challenge

Gulf Copper Energy Services Rope Teams Rise to the Challenge at Dali/Baltimore Bridge Incident

When disaster strikes, Gulf Copper Energy Services (GCES) is ready to respond. This month, our highly skilled rope access team demonstrated their expertise and dedication in a critical situation involving the Dali/Baltimore Bridge. When a vessel collided with the bridge, causing significant damage and threatening the integrity of the structure, GCES was called upon to provide essential rigging support for the removal of unstable cargo containers.

Our rope team, renowned for their experience in challenging environments, worked tirelessly alongside other emergency responders to secure the area and develop a safe removal plan. Using specialized rigging techniques and their in-depth knowledge of rope access systems, our team safely removed the containers, preventing further damage to the bridge and ensuring the safety of everyone involved. This swift and effective response is a testament to the professionalism and dedication of our GCES rope access team, highlighting Gulf Copper’s commitment to providing exceptional services in even the most demanding situations.

Gulf Copper Proudly Supports Battleship Texas’ Historic Restoration

At Gulf Copper, we’ve always been honored to play a role in preserving history. That’s why we’re thrilled to be a part of the ongoing restoration of the Battleship Texas, a legendary World War II vessel that bravely fired the first shots on D-Day. This iconic ship, a symbol of American courage and resilience, served our country with distinction, participating in numerous battles and earning 11 battle stars.

The Battleship Texas Foundation, a dedicated non-profit organization, has embarked on an ambitious $35 million restoration project to ensure this historic ship can continue inspiring future generations. Gulf Copper is proud to be a partner in this effort, contributing our expertise and world-class facilities at the Gulf Copper Dry Dock & Rig Repair in Galveston, Texas.

The extensive restoration efforts, which have been underway since 2022, have already seen over 700 tons of steel replaced and the hull repainted. With the ship successfully refloated in March 2024, the focus is shifting towards restoring the interior spaces, replacing the wood deck, and finalizing the navigation bridge.

We firmly believe that the Battleship Texas is a national treasure that deserves to be preserved. It’s a tangible reminder of the sacrifices made by those who fought for our freedom.

Learn more about the Battleship Texas’ incredible journey and this historic restoration project:

KXAN News: Inside Battleship Texas’ Historic Comeback 80 Years After D-Day

https://www.kxan.com/news/texas/inside-battleship-texas-historic-comeback-80-years-after-d-day/

Battleship Texas New Home at Pier 21 in Galveston

GALVESTON, Texas – After years of planning, the Battleship Texas Foundation is nearing final agreements with both Landry’s Inc. and the Port of Galveston to dock the historic USS Texas permanently at Pier 21.

Tony Gregory, President/CEO of the Battleship Texas Foundation, announced Thursday that the Foundation is approximately 60 days away from signing contracts with both parties. Landry’s operates several attractions adjacent to Pier 21, including the Harbor House Hotel and Willie G’s Seafood & Steaks. If finalized, the agreements would provide a long-term home for the deteriorating but iconic 110-year-old battleship following recent restoration work.

Mark Ashwell, Director of Business Development at Gulf Copper Dry Dock & Rig Repair, where restoration on the USS Texas began in September 2022 stated, “This will be a great enhancement for Galveston City and its people, as it will keep the iconic battleship in Texas and improve the overall tourist experience on the island.

The Battleship Texas will allow people from all over the country to tour the battleship to feel nostalgic and see the once state-of-the-art technology and engineering marvel of the only remaining World War I Dreadnought.”

Battleship USS Texas Is Making One Hell of a Comeback

The USS Texas, a World War I-era battleship, is undergoing a $35 million repair effort in Galveston, Texas. While the ship is in dry dock, the Battleship Texas Foundation has been providing limited tours so visitors can see the damage to the hull and the repair efforts. The tours, which began last month and run every Sunday, are only open to visitors who are at least 16 years old and who adhere to a strict dress code. The USS Texas is the oldest surviving modern naval warship and has seen service in both world wars. After the repairs are completed, the foundation intends to relocate the ship to a new location, with Baytown, Galveston, and Beaumont expressing interest in hosting it.

IDIQ Announcement

Gulf Copper was one of the awardees on a combined $300,185,454 firm-fixed price indefinite-delivery/indefinite-quantity, multiple award contract for non-complex repair, maintenance, and modernization requirements of non-nuclear U.S. Navy amphibious (LHA, LHD, LPD and LSD) class ships homeported in or visiting Norfolk, Virginia. These efforts consist of Chief of Naval Operations scheduled docking and non-docking, continuous maintenance, and emergent maintenance availabilities of amphibious class ships to be performed in Norfolk, Virginia. Accordingly, the place of performance is Norfolk, Virginia where the Mid-Atlantic Maintenance Center (MARMC) will administer the contract. Delivery orders will be competitively awarded under this contract, which are to be performed in Norfolk, Virginia. Each of the contracts has an estimated ordering period of four years, which is expected to end in January of 2027.

Award of NOAA Henry Bigelow

Congratulations to Gulf Copper and Manufacturing being awarded the $3.9 Million Dry Docking and refurbishment of the NOAA vessel M/V Henry Bigelow. We look forward to a successful project under the guidance of Jonathan Hale and the Galveston project team of Craig Marston and Erik Stramblad.

SEACOSCO ‘AMAZON’ Stimulation Package

Gulf Copper Galveston shipyard completes the installation of the ‘Stimulation Package’ which includes electrical support, and piping system integrations for Schlumberger on the SEACOSCO Amazon vessel that will be supporting the Exxon Mobil project in Guyana.

The project took approximately 6 weeks alongside at our Galveston facility and encompassed around 20 personnel dedicated to the project round the clock.